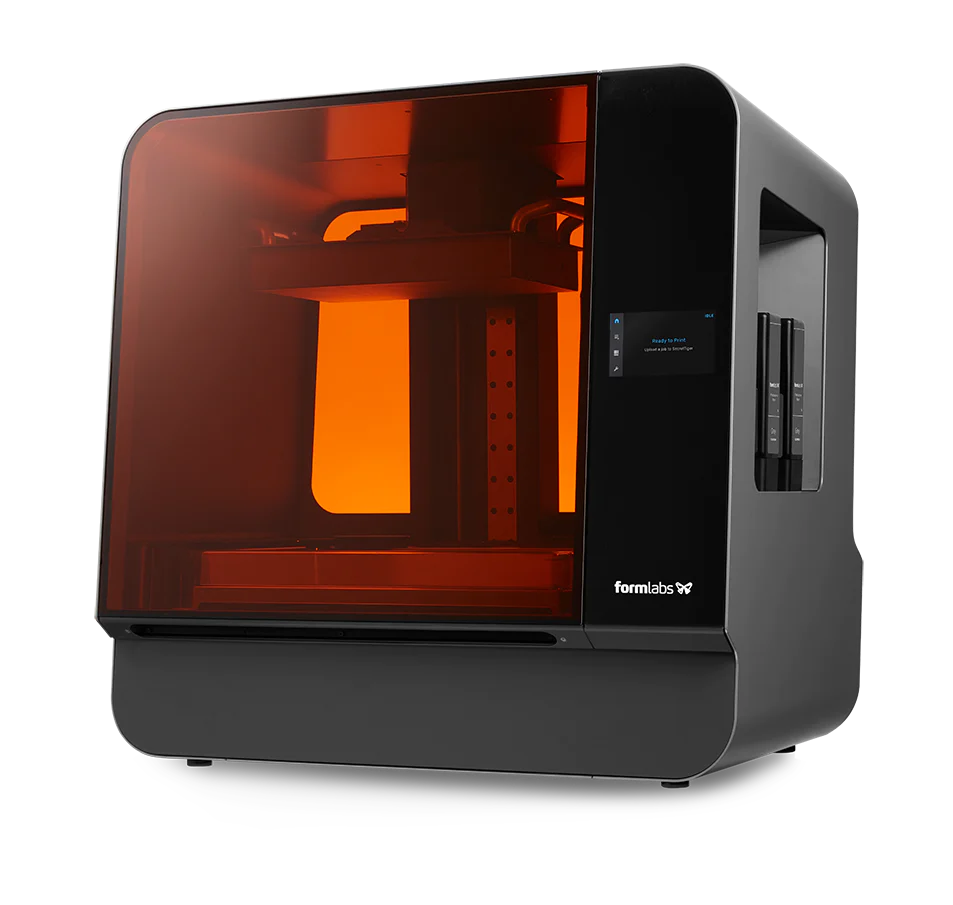

- Technology: Low Force Stereolithography (LFS)™

- XY Resolution: 25 microns

- Laser Spot Size: 85 microns

-

Laser Power: Two 250 mW lasers

- Build Volume (W x D x H):

33.5 × 20 × 30 cm (13.2 × 7.9 × 11.8 in) - Layer Thickness: 25 – 300 microns

- Usable with Biocompatible Formlabs Resins

- Form 3BL 3D Printer

- Form 3BL Build Platform

- Form 3BL Resin Tank

- Form 3 Finish Kit (Rinse Bucket and Cleaning Tools)

- 1 Year Professional Services Plan

OPTIMIZED FOR LARGE SCALE PRINTING

- The Form 3L has roughly 5x the build volume of the Form 3

- Two Parallel Light Processing Units (LPUs) and accepts two resin cartridges at the same time to feed large prints

- Accepts 2 resin cartridges at the same time to feed large prints

FLAWLESS PRINTS, EVERY TIME.

- LFS (Low Force Stereolithography) 3D printing balances detail and speed.

- The optical system maintains a precise, dense laser spot to ensure accurate, repeatable prints.

- Easy clean-up and smoother parts with tear-away light-touch supports.

NONSTOP PRINTING.

- Integrated sensors monitor and maintain ideal conditions for consistent performance over time.

- Switch between materials in seconds with a simple cartridge system.

- User-replaceable components and foolproof design maximize uptime.

GROWS WITH YOUR BUSINESS.

- Meet demand, now and forever. Easily transition from one to many with systems that scale.

- Don’t wait. Print from anywhere as soon as you have files with Remote Print.

- Works well with teams. Monitor and manage prints and teams with PreForm and Dashboard. Track individual usage and adjust the print queue when you need to prioritize.

Reviews

There are no reviews yet.